Blade³.ai Services | AI-Powered Wind Turbine Inspection & Analytics

Smarter Maintenance. Safer Operations. Sustainable Performance.

Blade³.ai delivers a complete suite of AI-driven inspection and analytics services designed to keep wind farms operating at peak efficiency.

From autonomous drone inspections and infrared imaging to predictive maintenance and 3D digital twin modeling, every Blade³.ai service helps operators reduce downtime, cut costs, and extend turbine lifespan — all through real-time intelligence.

⸻

Blade³.ai Services

Smarter Maintenance. Safer Operations. Sustainable Performance.

Blade³.ai provides a complete suite of AI-driven inspection and analytics services that help wind operators manage turbines with greater accuracy, efficiency, and insight.

Through autonomous drone inspections, infrared imaging, predictive maintenance, and 3D digital twin modeling, Blade³.ai enables renewable energy companies to reduce downtime, cut operational costs, and extend turbine lifespan — all powered by intelligent automation.

⸻

Our Core Services

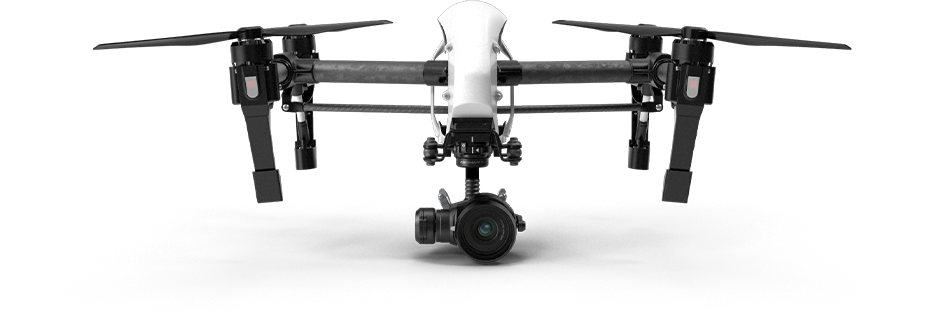

1. Drone Wind Turbine Inspection

Autonomous drones capture ultra-high-resolution and thermal imagery of wind turbines from every angle.

AI algorithms instantly identify cracks, lightning damage, surface erosion, and coating wear — delivering actionable inspection results within hours, not days.

This eliminates manual climbs and dramatically improves safety for technicians.

⸻

2. Infrared Turbine Inspection

Thermal imaging reveals temperature variations that indicate stress, friction, and internal faults before they’re visible to the human eye.

Blade³.ai’s AI platform interprets this data in real time, helping operators prevent costly failures and optimize maintenance schedules based on early thermal warning signs.

⸻

3. Predictive Turbine Maintenance

Blade³.ai uses machine learning to forecast turbine wear and component degradation.

Our predictive models analyze performance data, weather conditions, and inspection results to generate health scores for every turbine — allowing operators to plan maintenance proactively instead of reactively.

This approach reduces emergency repairs, downtime, and unnecessary service costs.

⸻

4. 3D Turbine Modeling & Digital Twins

Each inspection is transformed into a detailed 3D digital model that mirrors the real turbine’s structure and condition.

These digital twins allow engineers to visualize surface damage, compare historical data, and track structural changes over time.

Operators gain full transparency and precision in asset management, supported by cloud-based collaboration tools.

⸻

5. Wind Farm Performance Analytics

Blade³.ai integrates turbine performance data, inspection imagery, and environmental inputs into a single AI-powered dashboard.

The platform automatically benchmarks turbines, identifies inefficiencies, and provides predictive insights that optimize output and extend asset lifespan.

Operators can monitor performance trends, detect power loss, and measure the impact of maintenance decisions — all in real time.

⸻

Why Operators Choose Blade³.ai

• Real-time inspection results powered by AI

• Cloud-based dashboards accessible anywhere

• 95%+ defect detection accuracy and predictive precision

• Up to 70% reduction in inspection cost and time

• Seamless integration with CMMS and ERP systems

• Compliance-ready data and automatic documentation

⸻

Schedule a Demo

Experience how Blade³.ai transforms renewable energy operations through intelligent automation.

Request a live demo to see how our AI platform unifies drone inspections, predictive analytics, and digital twin modeling for smarter, safer, and more sustainable turbine management.

Schedule your demo at Blade³.ai

⸻

Benefits of Blade³.ai Services

Unified AI Platform

Blade³.ai connects drone inspections, infrared imaging, and analytics into one intelligent system.

Impact: Streamlined operations and centralized data management.

Autonomous Drone Inspections

Automated UAV missions capture turbine imagery safely and efficiently, removing human exposure to risk.

Impact: Zero-risk, faster inspections.

AI-Powered Analytics

Deep learning detects and classifies turbine defects faster and more accurately than manual review.

Impact: 95%+ accuracy, instant results.

Predictive Maintenance

AI forecasting anticipates wear and failure trends, allowing repairs to be scheduled at the optimal time.

Impact: Reduced downtime and repair costs.

3D Digital Twins

Interactive 3D models visualize turbine condition and track changes over time for precise lifecycle analysis.

Impact: Full asset transparency and traceability.

Real-Time Cloud Access

All inspection data and performance metrics are available instantly from any device or location.

Impact: Faster decision-making and team collaboration.

Cost Efficiency

Automation reduces labor, travel, and equipment costs while improving accuracy and reliability.

Impact: Up to 70% savings in O&M expenses.

Sustainability

Optimized maintenance planning reduces waste, extends asset lifespan, and lowers environmental impact.

Impact: Greener, more efficient renewable operations.

Schedule a Demo

Experience how Blade³.ai transforms data into intelligence across your entire wind portfolio.

Request a live demo and see how our unified AI platform delivers smarter inspections, predictive maintenance, and performance optimization.

About Blade³.ai

Blade³.ai is an AI-powered wind turbine inspection and analytics platform that helps operators optimize performance, reduce downtime, and extend the lifespan of renewable energy assets.

Through autonomous drones, infrared imaging, and predictive intelligence, Blade³.ai delivers real-time insights that make wind energy safer, smarter, and more sustainable.

Commitment to Sustainability

At Blade³.ai, we believe innovation should power a cleaner future.

Our mission is to help the renewable energy industry achieve net-zero emissions through intelligent automation, proactive maintenance, and smarter analytics.

Legal

© 2025 Blade³.ai. All rights reserved.