Frequently Asked Questions | Blade³.ai

AI-Powered Wind Turbine Inspection, Maintenance & Analytics

Welcome to the Blade³.ai FAQ — your guide to understanding how our AI-driven turbine inspection and analytics platform helps operators achieve safer, faster, and more efficient wind energy maintenance.

Below are answers to the most common questions about our technology, drone inspections, predictive maintenance, and digital twin solutions.

1. What is Blade³.ai?

Blade³.ai is an AI-powered wind turbine inspection and analytics platform that combines drones, infrared imaging, and predictive intelligence to help operators reduce downtime, cut maintenance costs, and extend turbine lifespan.

Our system detects cracks, erosion, and hidden thermal stress in real time — providing actionable data for smarter renewable energy operations.

⸻

2. How does Blade³.ai work?

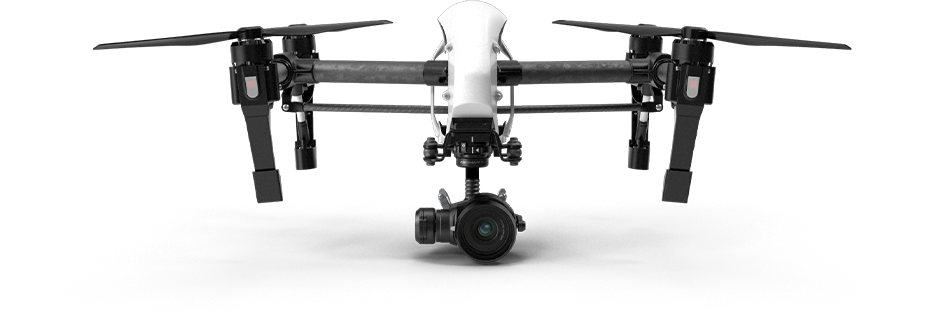

The process begins with autonomous drones capturing high-resolution and thermal images of turbine blades, towers, and nacelles.

That data is then processed by our AI engine, which automatically detects damage, classifies defects, and ranks severity levels.

Results are visualized through 3D digital twins and shared instantly via our cloud-based dashboard — delivering full visibility, predictive forecasting, and maintenance planning in one system.

⸻

3. What types of damage can Blade³.ai detect?

Blade³.ai identifies a wide range of surface and internal turbine issues, including:

• Cracks and delamination

• Leading-edge erosion

• Lightning strike damage

• Thermal hotspots and friction stress

• Paint and coating deterioration

• Corrosion and tower joint fatigue

Infrared imaging also detects hidden structural anomalies before they lead to mechanical failure.

⸻

4. How accurate is Blade³.ai’s AI inspection technology?

Our computer vision and machine learning models achieve over 95% detection accuracy, consistently outperforming manual inspections.

AI ensures standardized reporting across all turbines and eliminates human subjectivity, improving both precision and repeatability.

⸻

5. What are the benefits of using drones for turbine inspections?

Drone-based inspections eliminate the need for rope access, scaffolding, or manual climbs — drastically improving safety and efficiency.

Autonomous UAV missions capture full 3D and thermal data within hours, cutting inspection time by up to 90% and reducing operational costs by 70% or more.

⸻

6. What is a 3D digital twin, and how does it help?

A 3D digital twin is a virtual model of a turbine built from drone inspection data.

It mirrors every blade and component in detail, enabling engineers to visualize damage, compare historical changes, and simulate future degradation.

Digital twins provide permanent records for audits, warranties, and predictive maintenance programs.

⸻

7. How does Blade³.ai use predictive maintenance?

Blade³.ai’s AI forecasting models analyze inspection and performance data to predict when maintenance should occur.

Instead of relying on fixed schedules, the platform enables condition-based servicing — helping operators fix problems before they become failures.

⸻

8. Can Blade³.ai operate in offshore environments?

Yes. Blade³.ai’s drones are designed for marine-grade operation, optimized for wind, glare, and movement at sea.

Our platform supports both onshore and offshore wind farms, delivering real-time data analysis from any location worldwide.

⸻

9. How much does a turbine inspection cost with Blade³.ai?

Pricing depends on project size and location, but the average AI-based drone inspection costs between $300 and $500 per turbine — significantly less than manual methods, which can exceed $1,000 per turbine.

Blade³.ai also offers subscription and enterprise plans for fleet-scale operations.

⸻

10. How quickly can I access my inspection results?

Results are available in real time.

Our AI system processes images as drones are still flying, meaning defect reports, thermal maps, and 3D models can be viewed immediately after the mission concludes.

⸻

11. Does Blade³.ai integrate with other platforms?

Yes. Blade³.ai integrates seamlessly with CMMS, ERP, and renewable asset management systems, enabling automatic work order creation, performance tracking, and compliance reporting.

Data can be exported in PDF, CSV, or JSON formats for easy collaboration.

⸻

12. How does Blade³.ai improve sustainability?

By optimizing inspection schedules, reducing unplanned maintenance, and extending turbine lifespan, Blade³.ai significantly reduces waste, travel, and emissions.

Each inspection helps wind farms achieve better energy efficiency and contributes to a more sustainable global grid.

⸻

13. How can I get started with Blade³.ai?

It’s easy to begin.

You can schedule a demo, request pricing, or contact our team through https://blade3.ai.

We’ll assess your turbines, customize your inspection plan, and help you implement AI analytics that fit your operational needs.

⸻

Key Benefits at a Glance

• 95%+ AI detection accuracy

• Up to 90% faster inspection turnaround

• 70% reduction in maintenance costs

• Zero-risk drone operations (no human climbs)

• Predictive maintenance and thermal analytics

• Cloud-based 3D reports and digital twins

• Scalable for both onshore and offshore wind farms

About Blade³.ai

Blade³.ai is an AI-powered wind turbine inspection and analytics platform that helps operators optimize performance, reduce downtime, and extend the lifespan of renewable energy assets.

Through autonomous drones, infrared imaging, and predictive intelligence, Blade³.ai delivers real-time insights that make wind energy safer, smarter, and more sustainable.

Commitment to Sustainability

At Blade³.ai, we believe innovation should power a cleaner future.

Our mission is to help the renewable energy industry achieve net-zero emissions through intelligent automation, proactive maintenance, and smarter analytics.

Legal

© 2025 Blade³.ai. All rights reserved.