AI Turbine Inspection | Intelligent Drone & Infrared Blade Analysis by Blade³.ai

Smarter Inspections. Predictive Results. Total Control.

Blade³.ai brings the next generation of AI turbine inspection — combining drones, infrared imaging, and advanced analytics to detect defects, forecast degradation, and streamline turbine maintenance.

With real-time data and predictive AI models, wind farm operators can make faster, safer, and more profitable decisions — minimizing downtime while maximizing turbine output.

What Is AI Turbine Inspection?

AI turbine inspection uses artificial intelligence and computer vision to analyze high-resolution drone imagery of wind turbines.

Instead of manual review, Blade³.ai’s algorithms automatically detect cracks, erosion, lightning strikes, and thermal anomalies in real time.

The result is a faster, safer, and far more consistent evaluation of turbine condition — powered by automation and precision engineering.

⸻

How Blade³.ai Transforms Turbine Inspections

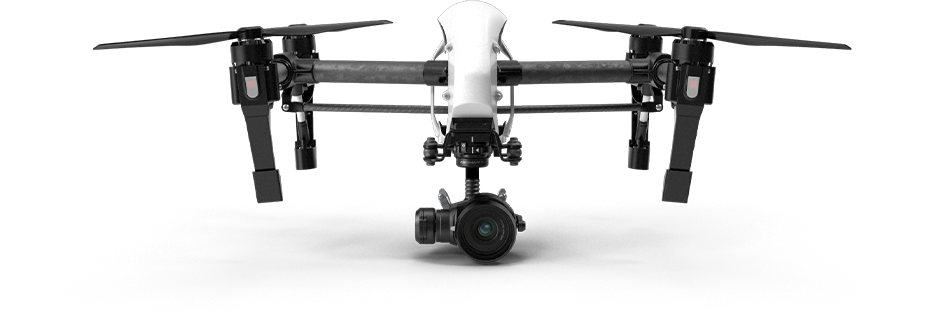

1. Autonomous Drone Flight

Drones fly pre-programmed routes around turbines, capturing 4K visual

and thermal data from every angle.

2. AI Image Processing

Blade³.ai’s neural networks classify and label defects automatically —

identifying even micro-fractures invisible to human eyes.

3. Thermal & Infrared Analysis

Heat-map overlays reveal structural stress, friction points, and internal

degradation early in their life cycle.

4. Health Scoring & Predictive Analytics

Each turbine receives an AI-generated health score and predictive trend

analysis to forecast future performance.

5. Automated Reports

Blade³.ai produces instant, shareable reports with severity ranking,

3D modeling, and maintenance recommendations.

What Blade³.ai Detects

• Surface cracks and delamination

• Lightning strike damage

• Leading-edge erosion

• Paint and coating degradation

• Tower corrosion

• Thermal hotspots and friction wear

• Structural misalignment or imbalance

Each anomaly is automatically geotagged, scored, and visualized

on an interactive 3D model for easy tracking over time.

⸻

Why Operators Choose Blade³.ai

• Real-time analytics — actionable insights while drones are still flying

• 3D digital twins for full turbine visibility

• Cloud access — review, share, and export inspection data instantly

• Predictive health scores — anticipate maintenance before failures occur

• Integration-ready — connects with CMMS, ERP, and asset-management systems

Applications

Blade³.ai’s AI turbine inspection is trusted across both onshore and offshore wind projects — from large utility-scale farms to independent operators.

It’s ideal for routine maintenance, post-storm assessments, warranty claims, and end-of-life extension programs.

Benefits of AI-Based Turbine Inspection

Blade³.ai’s AI turbine inspection technology combines drone automation, infrared analytics, and deep learning to help wind operators detect damage faster, prevent failures, and extend turbine lifespan.

| Benefit | Description | Impact |

|---|---|---|

| Accelerated Inspections | Drones and AI process turbine data simultaneously, completing inspections for entire wind farms in under 48 hours. | Up to 90% faster turnaround |

| High Detection Accuracy | Machine-learning models detect cracks, erosion, and lightning damage with unmatched precision and consistency. | 95% + verified accuracy |

| Predictive Maintenance | AI forecasts future degradation trends and schedules maintenance before costly failures occur. | Reduced downtime & repairs |

| Enhanced Safety | Fully autonomous inspections remove the need for rope access or elevated work, eliminating human-risk exposure. | Zero on-site hazards |

| Cost Efficiency | Automated data capture and instant analysis lower operational costs by reducing labor and site visits. | 60–70% cost reduction |

| Real-Time Analytics | Live AI processing provides immediate defect mapping, temperature overlays, and health scoring during flight. | Instant visibility |

| Standardized Data | Consistent AI methodology ensures repeatable results and comparable metrics across sites and seasons. | Reliable benchmarking |

| Sustainability | Fewer truck rolls and longer blade lifespan reduce CO₂ emissions and promote cleaner, more efficient wind operations. | Lower carbon footprint |

Blade³.ai helps operators move from reactive maintenance to intelligent, predictive operations — combining automation, AI, and sustainability for a smarter generation of wind turbine management.

U.S. States with Wind Turbines (2025 Estimates)

Wind power is active in more than 40 U.S. states, with Texas, Iowa, and Oklahoma leading the nation in installed capacity. These figures represent approximate onshore and offshore capacity in megawatts (MW) as of 2025.

| Rank | State | Installed Capacity (MW) |

|---|---|---|

| 1 | Texas | 42,000 |

| 2 | Iowa | 12,500 |

| 3 | Oklahoma | 11,000 |

| 4 | Kansas | 9,000 |

| 5 | Illinois | 8,500 |

| 6 | California | 6,500 |

| 7 | Minnesota | 5,000 |

| 8 | Colorado | 4,500 |

| 9 | North Dakota | 4,000 |

| 10 | Indiana | 3,000 |

| 11 | Nebraska | 3,500 |

| 12 | New Mexico | 3,800 |

| 13 | South Dakota | 3,300 |

| 14 | Michigan | 2,500 |

| 15 | Wyoming | 2,200 |

| 16 | Oregon | 2,100 |

| 17 | Washington | 2,000 |

| 18 | New York | 1,900 |

| 19 | Pennsylvania | 1,600 |

| 20 | Montana | 1,500 |

| 21 | Idaho | 1,200 |

| 22 | Maine | 1,100 |

| 23 | Arizona | 800 |

| 24 | West Virginia | 700 |

| 25 | Wisconsin | 650 |

| 26 | North Carolina | 550 |

| 27 | Missouri | 500 |

| 28 | Georgia | 250 |

| 29 | Virginia | 200 |

| 30 | Alaska | 100 |

Texas leads by a wide margin, followed by the Midwest corridor of Iowa, Oklahoma, and Kansas — representing the strongest regions for Blade³.ai’s autonomous inspection deployments across the United States.

Schedule a Demo

Experience how Blade³.ai transforms drone inspections into predictive turbine intelligence.

Request a live demo and see how our real-time AI analysis, thermal visualization, and automated reports can help your wind farm achieve zero unplanned downtime.

About Blade³.ai

Blade³.ai is an AI-powered wind turbine inspection and analytics platform that helps operators optimize performance, reduce downtime, and extend the lifespan of renewable energy assets.

Through autonomous drones, infrared imaging, and predictive intelligence, Blade³.ai delivers real-time insights that make wind energy safer, smarter, and more sustainable.

Commitment to Sustainability

At Blade³.ai, we believe innovation should power a cleaner future.

Our mission is to help the renewable energy industry achieve net-zero emissions through intelligent automation, proactive maintenance, and smarter analytics.

Legal

© 2025 Blade³.ai. All rights reserved.